Pharmaceutical Industry

AKCP sensorProbe, sensorProbe+ & securityProbe Base Units and Smart Sensors for:

Environmental Monitoring

Monitor environmental conditions and maintain cold storage temperatures for food safety requirements.

Custom Reporting

Continuous data logging of storage conditions for facilities management and to demonstrate compliance.

Alert Notifications

Immediate alerts once pre-defined thresholds are met via physical alerts, email and SMS* text messages.

Why Pharmaceutical Businesses Should Invest in Environmental Monitoring

Airflow, temperature, and humidity directly influence potency, sterility, and compliance. Continuous monitoring keeps these variables in check—so batches stay safe and audits go smoothly.

Robust environmental monitoring reduces contamination risk by ensuring proper airflow distribution and stable clean-room conditions. Tight temperature control preserves the efficacy of temperature-sensitive products, while precise humidity control prevents moisture-driven issues that degrade active ingredients or alter dissolution rates.

Real-time data, alerts, and traceable logs empower proactive corrections and support GMP expectations (ALCOA+). The result is fewer deviations, stronger product quality, and confidence from manufacturing through storage.

- Reduce cross-contamination and batch loss

- Maintain temperature/humidity within validated ranges

- Meet GMP and audit requirements with clear evidence

- Speed root-cause analysis and CAPA effectiveness

- Protect stability studies & sensitive materials

- 24/7 alerts to act before small drifts become failures

Ready to de-risk your facility? Get a tailored sensor and alert plan for each room and process step.

Talk To A SpecialistSensorProbe+ & SecurityProbe Base Units and Smart Sensors for Pharmaceutical Industry

See below for our most popular configurations for laboratory temperature measurement, or click here to view all of our Base Units and Smart Sensors.

SensorProbe2+ | SP2+

- Features:

- Virtual Sensors

- IP based, including SNMPv3 (optional license), HTTPS, VPN

- Supports 4 Intelligent Sensors or up to 20 Dry Contacts

SensorProbeX+ | SPX4+

- Features:

- (4) Smart Sensor Inputs

- Equipped with Ethernet, Modbus RS485, EXP and BEB communications

- Notification by SNMP, Email, SMS (optional modem required)

Temperature & Humidity Smart Sensors

- Features:

- Quick and simple set-up and configuration

- Receive email and SMS alert notifications

- Supports SNMP polling

- Easy firmware updates

Liquid Detection Smart Sensors

- Features:

- Quick and simple set-up and configuration

- Receive email and SMS alert notifications

- Supports SNMP polling

- No calibration required

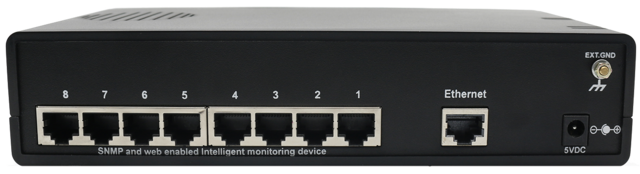

SensorProbeX+ | SPX8+

- Features:

- (8) Smart Sensor Inputs

- Equipped with Ethernet, Modbus RS485, EXP and BEB communications

- Up to 80 virtual sensors (Delete this as it will be confusing)

Airflow Smart Sensor

- Features:

- Quick and simple set-up and configuration

- Receive email and SMS alert notifications

- Supports SNMP polling

- Easy firmware updates

Smoke Detection Smart Sensors

- Features:

- Detects the presence of smoke

- LED indicator visually indicates alarm status

- Receive email and SMS alert notifications

- Supports SNMP polling

Central Management Software Solution

By connecting your sensorProbe+ & securityProbe base unit to the AKCPro Central Management software, customers can manage base units and sensors across multiple sites or facilities from a single dashboard.

Need more information?

Feel free to contact us should you have any questions or if you need more information!