Automated Monitoring and Data Logging for Industrial Manufacturing Processes

In manufacturing processes and industrial facilities, ensuring precise control over temperature, humidity, and other environmental factors is imperative. This is vital for maintaining a consistent, regulated state of control in fabrication and manufacturing processes to ensure the production of high-quality products.

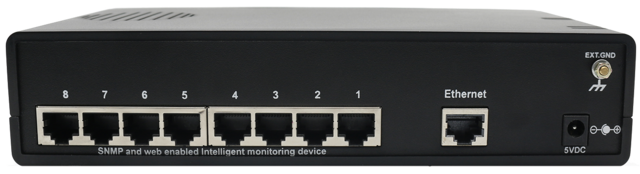

Discover the capabilities of our sensorProbe+ and securityProbe monitoring systems in a live, real-world environment.

Explore our sensorProbe, sensorProbe+ and securityProbe monitoring systems in a live real-world environment.